Structural Health Monitoring, Assessment & Rehabilitation

What We Do?

We provide solutions for health monitoring & assessment of civil structures for understanding the global behavior by instrumentation at strategic locations. Finding parameters such as acceleration, modal frequencies, displacements, stresses, strains, and forces induced under dynamic loading.

Download Our Brochure

KDM Structural Health Monitoring(SHM), Assessment & Rehabilitation

Our Services

- Structural Health Monitoring

- Long-Term (Live Monitoring) Monitoring of Structures.

- Modal Analysis

- Condition Assessment and Condition Mapping.

- Consultancy Services for suggesting Remedial Measures, Structural Strengthening, and Rehabilitation.

- Non-destructive / Semi-destructive testing to check the Integrity of Structures.

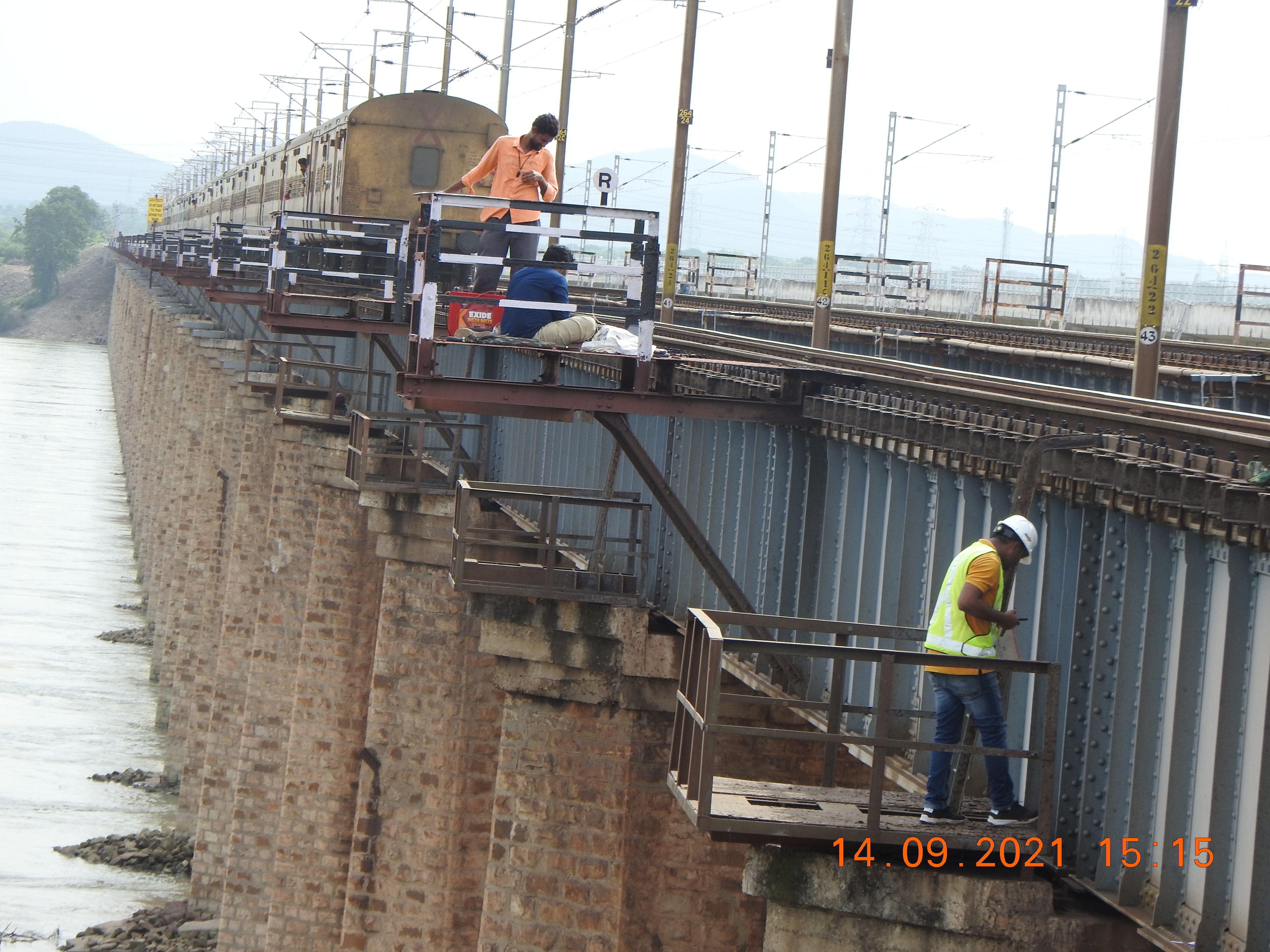

- Rail Structure Interaction studies and Instrumentation Works on Railway Bridges.

- Bridge Load Testing,

- Pier Tilt / Rotation Monitoring

- Scour Monitoring

- Water Level Monitoring

- Drone Inspection

- Complete Temperature Monitoring

- Strain Monitoring

Our Infrastructure

We have been collaborating closely with various research institutes to integrate the hardware and software at our own laboratory to make use of various sensors, Automated data collection and analysis for structural monitoring for a complete Design-to-service Solutions.

- Accelerometer

- Inclinometer/Tilt Sensors

- LASER scanning

- IoT devices

- RFIDs (Radio Frequency Identification)

- Acoustic emissions

- MEMS

- Velocity Transducers

- Temperature Sensors

- GPS

- Weather Stations

- Water Level Monitoring

- Scour Monitoring

- Strain Measurement

What is SHM ?

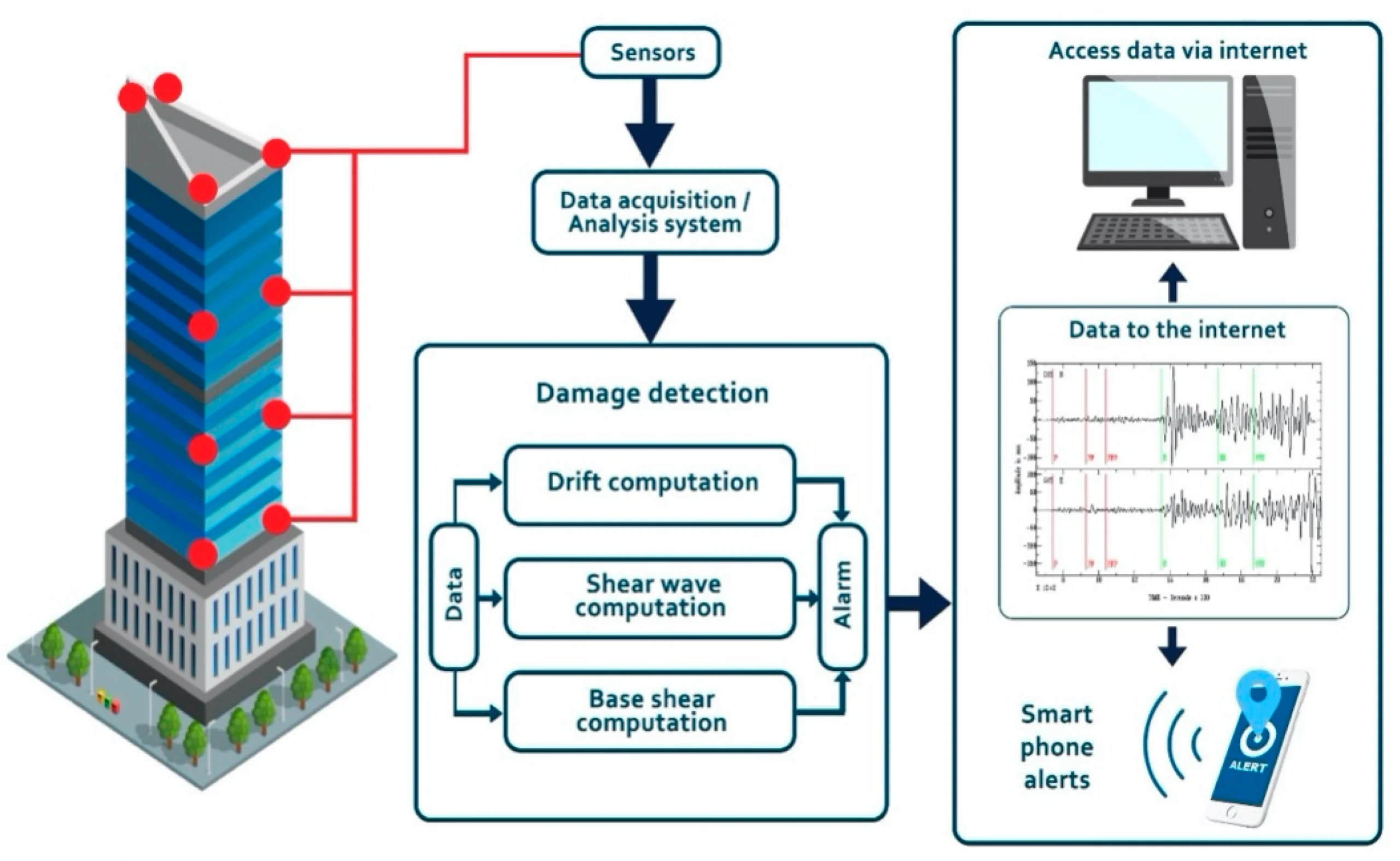

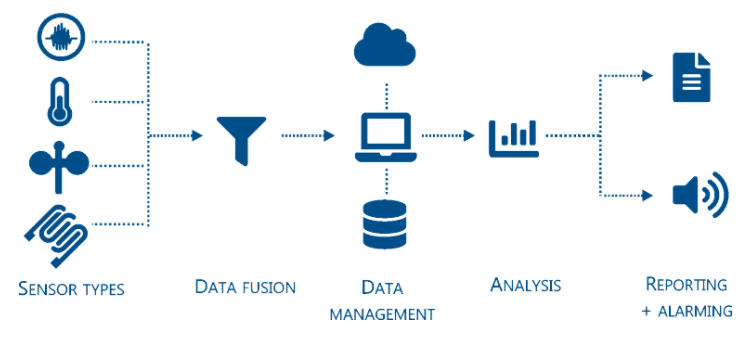

The Process of systematizing a damage detection and characterization techniques. It is a non-destructive in-situ structural evaluation method that involves several types of sensors embedded or attached to the structures for the purpose of assessing the actual conditions of the structures. Global and local structural behavior are considered on the basis of real-time data aggregation.

Why SHM ?

- SHM provides a tool to ensure structural integrity and safety, detecting the growth of damages, and valuating the performance of infrastructures.

Applications of SHM

SHM Work for Critical Structures like:

- Bridges

- Rail Structures

- Wind Turbines

- Tunnels

- Power Plants and Dams.

- Historic Buildings

- Offshore Structures (Ports, Harbors)

- All Types of Structural Applications

SHM Involves

- Performance Enhancement of an Existing Structure

- Identifying Structures Affected by Any External Factors

- Continuous Health Monitoring

- Reduction of Uncertainty

- Discovering Hidden Structural Reserves

- Examining Deficiencies

- Structure’s Long Term Quality Promotion

- Asset and Engineering Knowledge Elevation

- Asset Lifespan Extension

- Post-earthquake Structural Integrity

- Operational Evaluation

- Improve Performance (Safety and Functionality) of Existing Structures

- Help to Design Better Structures in the Future

- Observers to Assess the Structure’s Condition and Its Remaining Life Span

- Data Feature Extraction

- Statistical Models Development

- Cost Reduction, Cost-effective Maintenance

Processing Phases of SHM

Installation Preprocessing

- Initial site visit and investigate to find and install the exact locations of the sensors.

- Make the surface suitable for installation of sensors with help of Epoxy glue, Magnetic base, clamps etc.

- Some sensors we can fix directly on the structural elements. Or else using ‘L’ clamp for sensor installation.

Power supply

- Most of the instruments are

working with DC power. We

are preferring Solar, battery

power, generator and direct

power supplies

Sensors

- We are using various sensors for various application.

- Like Accelerometer, tilt meter, strain gauge, displacement sensor, temperature sensor, load cell etc

Data aggregator

- Data acquisition from wireless and inertial sensors. Aggregator collecting sensor data.

- From this aggregator we can directly collect sensor data through Ethernet & SensorCloud, MicroUSB.

- Data is securely stored, viewed and analytic operations/alert set up.

Software’s

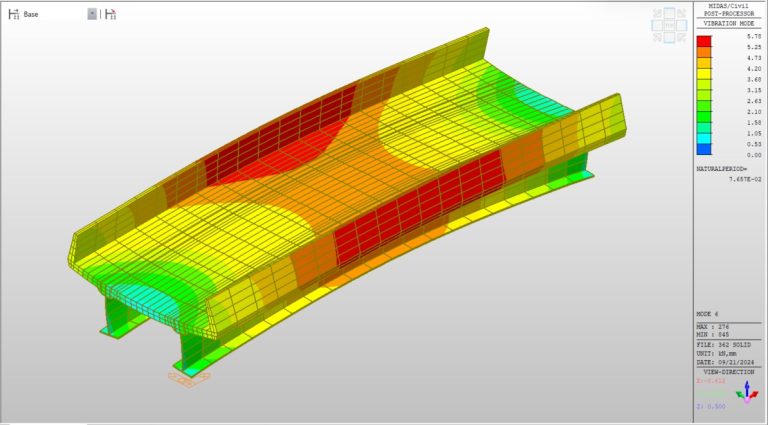

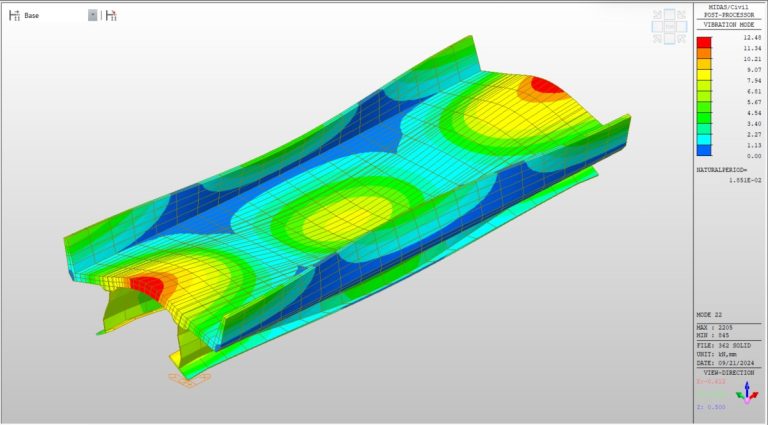

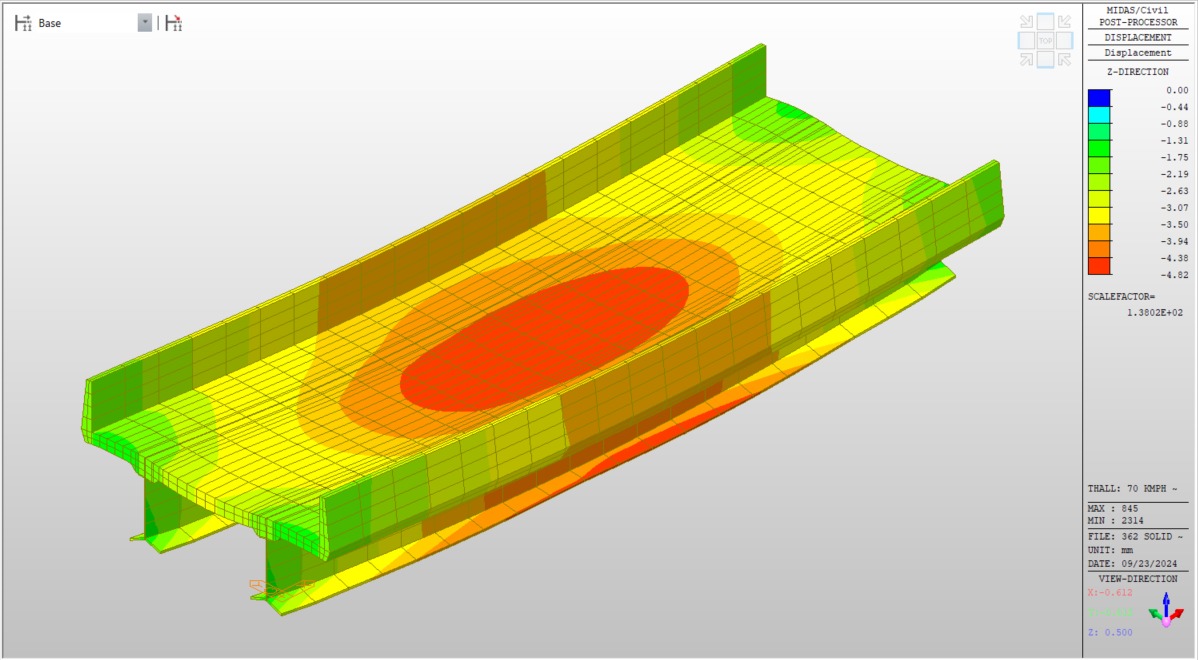

- MIDAS Software for Structural Modelling & Analysis.

- Sensor Connect is specially designed software for plotting the aggregator received data.

- Most of the instrument manufacturer providing their own software’s for analysis.

Advanced SHM Instrumentation & Data Aggregation

Accelerometer Sensor

The triaxial accelerometer allows high-resolution data acquisition. It can record vibrations up to ±8g with extremely low noise and drift. Derived vibration parameters allow for logarithmic monitoring of key performance indicators.

These wireless sensing systems are ideal for testing and measurement, remote monitoring, system performance analysis, and embedded applications.

Strain Gauge Sensor

A Strain gauge is a sensor whose resistance varies with applied force; it converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured.

When external forces are applied to a stationary object, stress and strain are the result.

Displacement sensors

An LVDT consists of a metal rod that moves inside an electrical coil. A force applied to the rod results in a displacement that affects the inductance of the coil.

It is a common type of electromechanical transducer that can convert the rectilinear motion of an object to which it is coupled mechanically into a corresponding electrical signal.

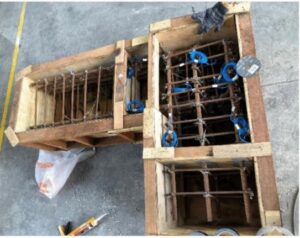

Load Cell

Most used load cell is the strain gage load cell.

Several strain gages mounted in a Wheatstone bridge configuration so that the application of a force causes a strain in the assembly the strain gages are measuring.

These devices are calibrated so that the force is directly related to the resistance change. pneumatic and hydraulic load cells translate force into

pressure measurements.

When force is applied to one side of the piston or diaphragm, the amount of pressure (pneumatic or hydraulic) applied to the other side to balance that force is measured.

Types of Installation

Long Term – Real Time Health Assessment

- Long-term – Real-Time Health monitoring

- One month to an unlimited number of months of continuous recording

- Offline, Online, and Cloud data aggregations

Short Term – Real Time Health Assessment

- Short-term – Real-Time Health Monitoring

- Summer, Winter, as the client request

- Offline, Online, Onsite, and Cloud data aggregations

Permanent installation while construction

- Permanently installed while construction.

- It’s life long monitoring methodology

- Low-cost instruments

- Internal monitoring method

Completed Projects

Navadgi Bridge (Karnataka)

Navadgi Bridge Rail Structure Interaction (RSI) Validation for Bridge No....

Read MoreJagdalpur Bridge (Chhattisgarh)

Jagdalpur Bridge Rail Structure Interaction (RSI) Validation For Bridge No....

Read MoreRaipur Bridge (Chhattisgarh)

Raipur Bridge Rail Structure Interaction (RSI) Validation For Bridge No....

Read MoreMancherial Godavari Bridge (Telangana)

Mancherial Godavari Bridge Structural Condition Assessment For Bridge No. 142...

Read MoreGadwal Bridge (Telangana)

Gadwal Bridge Vibration Analysis for Bridge No. 375 – Gadwal...

Read MoreRajamundry Bridge (Andhra Pradesh)

Rajahmundry Bridge Structural Health Monitoring for Bridge No. 248 –...

Read MoreBridge between Rahenbhata Titlagarh Station (Odisha)

Bridge between Rahenbhata-Titlagarh station Rail Structure Interaction (RSI) Validation for...

Read More![KDM Engineers [India] Pvt. Ltd.](https://kdmengineers.com/wp-content/uploads/2021/12/KMDLogoHorizontal-R-200x113.png)